It cannot be denied that there is a significant amount of data that needs to be analyzed in order to properly manage a warehouse. The one thing that always seems to bring warehouses down is the humans within it. While humans are designed to make quick decisions based on the information they have immediately available, they are often unable to see the big picture of the warehouse they are working in and cannot process all of the information available in a timely manner. Computers, on the other hand, can see and process all of this information instantaneously and create extremely detailed and directed sets of instructions for workers so that they aren't making decisions that work against the efficiency of the warehouse.

It cannot be denied that there is a significant amount of data that needs to be analyzed in order to properly manage a warehouse. The one thing that always seems to bring warehouses down is the humans within it. While humans are designed to make quick decisions based on the information they have immediately available, they are often unable to see the big picture of the warehouse they are working in and cannot process all of the information available in a timely manner. Computers, on the other hand, can see and process all of this information instantaneously and create extremely detailed and directed sets of instructions for workers so that they aren't making decisions that work against the efficiency of the warehouse.

Removing the Blinders

Warehouse management systems gather data from all parts of your warehouse, tracking product movement and conducting a statistical analysis of every decision that is made within your walls. This system can also pick out global trends in your organization, covering an even greater scale than small trends that occur in each department or location.

This amount of information is extremely difficult to organize and understand, much less show to employees who need to make important decisions. In most companies, these reports are only available months later, and the company is reactive instead of proactive. Warehouse management systems are capable of making meaning out of this information much faster, and as a result, they can provide answers in short order. The company using a warehouse management system is operating without blinders on and can control all locations and departments equally well.

Removing the Guesswork

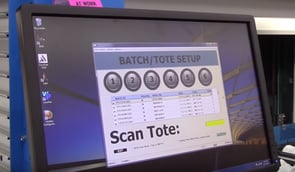

Now that your warehouse management system can see the big picture and make educated decisions for you, your warehouse is no longer subject to human errors that slow down productivity. By automating systems and giving employees step-by-step directions, you ensure that your team does not need to spend time figuring out where to go or repeatedly making return trips to the same part of the warehouse. Instead, they will have their tasks mapped out for them according to what the WMS has determined will be the fewest steps and the least amount of down time.

The WMS is also capable of forecasting the activity of all staff members and routing individuals to avoid traffic jams in your warehouse, a task that your team would never be able to manage in real time on their own. The end result is that productivity will increase because you will not be taking hits from inefficient routing, overcrowded work spaces, or small-scale human errors.

Warehouse management systems make it possible to increase productivity overnight by taking a larger view of how each individual in your warehouse is working. By taking the decision-making process away from people who cannot see the big picture and instead providing them with a detailed list of directions to work by, you cut even the smallest inefficiencies out of the system. After all, even a few minutes of down time each hour multiplied by the number of employees you have working and the number of hours they work each week can quickly become a large-scale disaster if not addressed. Warehouse management systems have the capacity to correct these errors at the planning and instruction levels before they become a problem.