No company that sells products ever really wants to issue refunds or see items returned. Still, returns are a reality for companies who want to please their customers. Whether it's products that don't work as expected, aren't the right size or color, or perhaps because of simple buyers' remorse, there are endless reasons customers choose to return products for exchanges and refunds.

Reid Curley

Recent Posts

RMAs and the Challenges of Reverse Logistics

Topics: warehouse management system

3 Hidden Costs of Paper-Based Warehouse Management

It is easy to see how paper-based warehouse management can be a slow and arduous process, but it may be harder to recognize some of the hidden costs associated with paper-based systems. While you are focused on direct costs, you could be missing the pennies and nickels that paper is costing you each and every day.

Topics: warehouse efficiency

Why Do Companies Still Use Paper-Based Warehouse Management?

In years past, paper-based warehouse management was the only option available to many companies. While some of them have since successfully implemented barcode labels and Warehouse Management Systems into their warehouse, other companies stick with paper. Cost, difficulty in rollout, and lack of understanding are all reasons that companies have avoided upgrading and have instead stayed with what seems like a "simpler" solution.

Topics: warehouse efficiency

Paper-Based Processes vs. Warehouse Management Systems

There are a wide variety of reasons that companies choose to transition from paper-based processes to using a Warehouse Management System. From data analysis and reporting to process verification and simplification, there are many ways such a system allows you to optimize your warehouse for efficiency and productivity.

Topics: warehouse management system

Why is Paper-Based Warehouse Management So Error Prone?

Paper-based warehouse management not only has a negative impact on warehouse efficiency, but it also presents many opportunities for human error. On an individual level, there is very little control over the paperwork each team member is filling out. Plus, without a computerized system cross-checking and verifying inputs, it takes much longer to identify errors and resolve them. In many cases, they go unaddressed altogether.

Topics: warehouse efficiency

ERP vs. WMS vs. WCS: The Real Differences

When you're new to the world of warehouse management, making sense of all the different automation and management options that are available can be confusing, to say the least. Even experienced warehouse managers and logistics executives sometimes have trouble defining the various types of systems used in their facilities.

Topics: warehouse management system

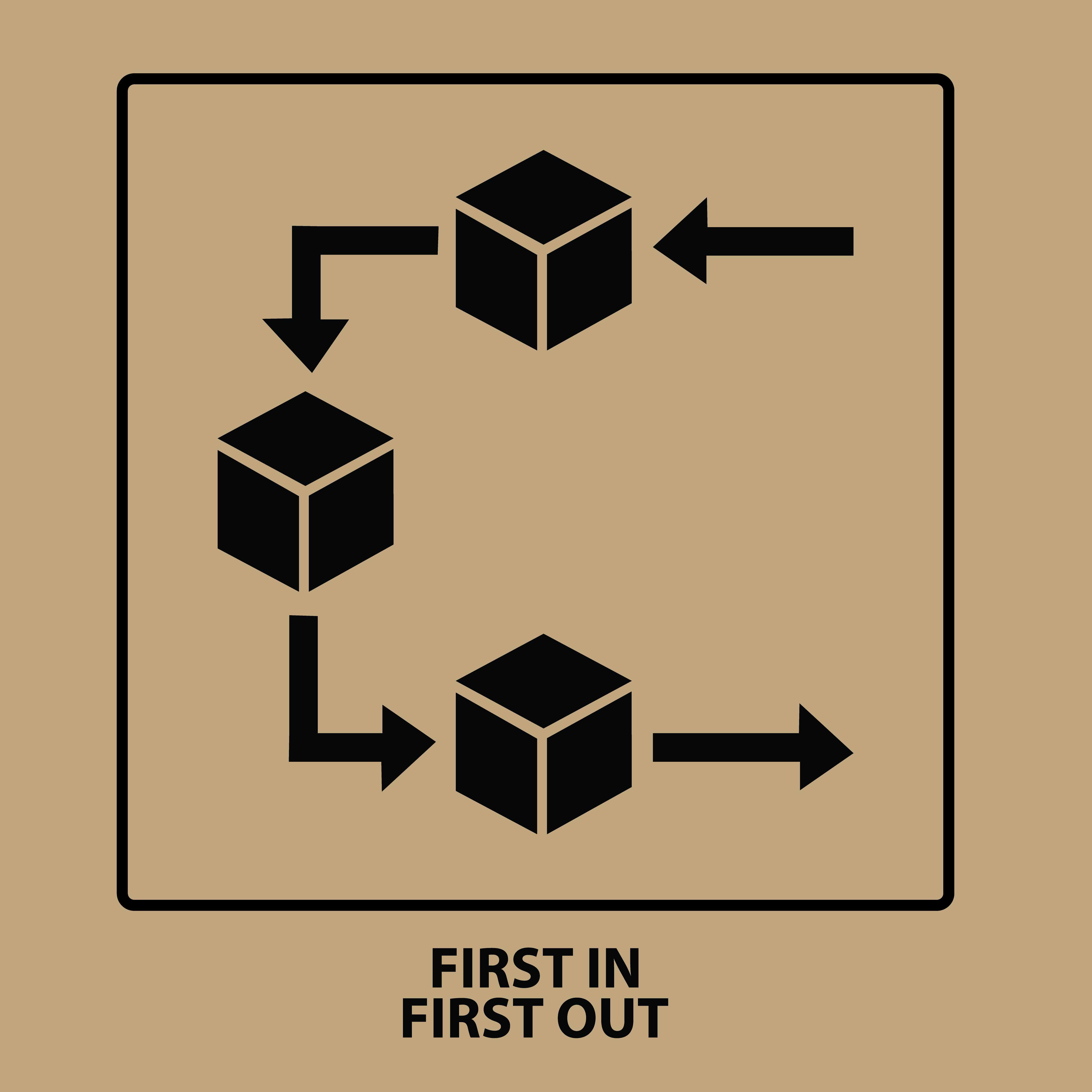

Pros and Cons of First In First Out (FIFO) Inventory Control

First In First Out (FIFO) rotation of physical goods is usually regarded as the gold standard for managing inventory. Despite this, many companies don't attempt to follow FIFO or do so only loosely. This can be due to obstacles that they face implementing a FIFO process, or a failure to fully appreciate the benefits that they can realize by strictly enforcing FIFO. Let's take a closer look at how FIFO works for physical inventory, where you might encounter issues, and when it is a good fit for your organization.

Topics: warehouse management system

The Benefits of Using the Right Warehouse Management System

Not all Warehouse Management Systems (WMS) are alike. When you have the right system, you can expect streamlined processes and increased efficiencies that elevate customer satisfaction and improve profitability. The wrong one, on the other hand, will make work harder and cut into your business's bottom line.

Topics: warehouse management system

Choosing the Right Warehouse Control Systems

The warehouse is the heart of many businesses. If you or one of your customers is considering purchasing material handling equipment or Automated Storage and Retrieval Systems (AS/RS), you're immediately confronted with the question of how to control that equipment and integrate it into the rest of the operation. Welcome to the world of Warehouse Control Systems (WCS). The knee-jerk reaction is to use the control systems provided by the OEM, but these are often limited. Whether they are insufficient to control the complex processes of the modern logistic-optimized warehouse or they are incompatible with the warehouse management systems being used, limited or non-existent warehouse control systems can cause issues.

Topics: warehouse management system

Avoiding Identity Crisis: 4 Benefits of Using Package Identification

Many warehouses only track the total quantity of stock-keeping units (SKUs) in a given location. These warehouses are missing opportunities to improve their operations by using Package IDs (PIDs). Package identification is a more precise way of handling incoming and outgoing products by identifying them in batches for put away, picking, and cycle counting.

Topics: warehouse efficiency